Versatile Integration with Various Liquid Types

Seamless Filling, Capping, and Labeling Solutions

Maintaining the taste, passion, and quality, our integrated solutions for liquid filling, capping, and labeling can seamlessly integrate with all types of liquid. Ensuring the highest efficiency and flexibility for our customers, we package their products durably and attractively. With our superior technology and expert team, we are pleased to meet even the most challenging filling and packaging needs.

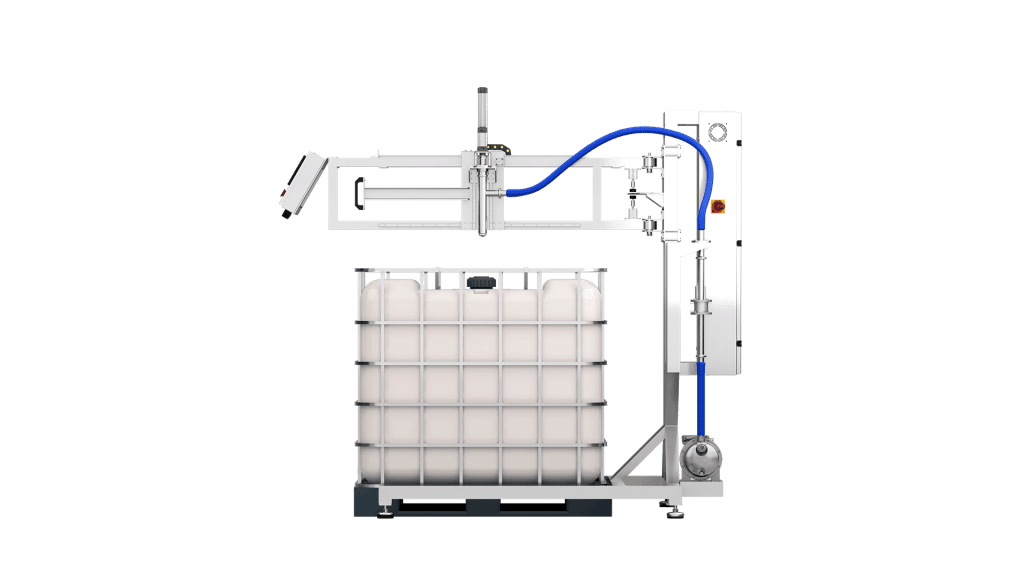

IBC Tank Filling Machine Introduction:

Our IBC tank filling machines are designed for the fast, accurate, and safe filling of industrial liquids. With advanced automation systems, these machines ensure controlled and error-free filling of chemicals, food products, cosmetics, and pharmaceuticals. Equipped with high-precision sensors, a secure filling mechanism, and a user-friendly interface, they boost operational efficiency while minimizing product loss. Our IBC tank filling solutions are compatible with liquids of varying viscosities, making them ideal for optimizing your production processes and ensuring consistent quality.

Enhancing Production Efficiency with Innovative Features

Advanced Automation for Streamlined Operations

Our cutting-edge filling, capping, and labeling line is equipped with advanced automation technology to streamline your production operations. Achieve efficiency, precision, and consistency in every step of the process, allowing you to meet high demands while maintaining top-notch quality standards. Experience the power of automation in optimizing your workflow and enhancing overall performance.

Filling, Capping & Labeling line Technical Specifications

| FILLING | CAPPING | LABELLING | ||

|---|---|---|---|---|

| Volume | 20 cc – 20000 cc | 20 cc – 20000 cc | WxL mm | 20-160 x 300 |

| Quantity | 200 pcs – 2400 pcs /h | 200 pcs – 2400 pcs/h | Coil Diameter | 300 mm |

| Sensitivity | 0,5% | ———– | Output Speed | 20 m/min |

| System | Electromagnetic Flow Meter (Endress+Houser), Volumetric or Loadcell | Pick and place with gripper head, pneumatic motor or head with controlling mechanical torque | Number of labeling | Max 3000 pcs/h |

| Roll diameter | 76 mm | |||

| Nozzle System | Nozzle with Internal Closing | Module Motor | Stepper motor | |

| Nozzle Quantity | 1 pcs – 12 pcs | |||

| Working Pressure | 6-8 Bar | 6-8 Bar | ——— | |

| Working Voltage | 380 Volt / 50 Hz | 380 Volt / 50 Hz | 220 volt / 50 Hz | |

| Control Voltage | 24V DC | 24V DC | 24V DC | |

| Control Unit | PLC | PLC | Coding unit | Optional |

| Cabin | Plexyglass | Plexyglass | ———- | |

| Product Sensor | Diffuse Optical Sensor | Diffuse Optical Sensor | Diffuse Optical Sensor | |

| Conveyor system | Moduler band | Moduler band | Moduler band | |

| Conveyor Motor | 380 Volt 0.37 kW | 380 Volt 0.37 kW | 380 Volt 0.37 kW | |

| Electricity consumption | 4 KW | 1,5 KW | 1 KW | |

| Conveyor Unit | AISI 304 Chassis with Moduler band | AISI 304 Chassis with Moduler band | AISI 304 Chassis with Moduler band | |

| Conveyor Width | 82.5mm-165mm | 82.5mm-165mm | 82.5mm-165mm | |

| Pneumatic materials | FESTO/SMC | FESTO/SMC | There is no label | Optional |

Quality Assurance Driven by Innovation

Our commitment to quality is at the core of our innovative processes. By integrating the latest technologies and best practices, we ensure that every product meets the highest standards of excellence.

Advanced Testing Procedures

Our advanced testing procedures guarantee that each product undergoes thorough quality checks to maintain consistency and meet industry benchmarks.

Continuous Improvement

Through continuous improvement initiatives, we aim to enhance our processes and constantly raise the bar for quality assurance in production.

Traceability and Transparency

Our transparent and traceable production process ensures accountability and allows for detailed tracking of each product through its journey from creation to distribution.

Maximizing Efficiency Through Integrated Solutions

Our integrated approach combines cutting-edge technology and expert craftsmanship to optimize efficiency and streamline your production process. Experience unparalleled performance and reliability with our comprehensive solutions.

Process Optimization

Our solutions are designed to enhance workflow efficiency, reducing bottlenecks and improving overall productivity. Maximize your output with optimized processes.

Quality Assurance

Quality is at the core of everything we do. Our stringent quality assurance measures ensure that every product meets the highest standards of excellence.

Flexible Configurations

With versatile and adaptable configurations, our solutions cater to your changing needs and evolving production requirements. Stay agile and responsive with our flexible setups.